Construction

Before I started building the hand I designed it with AUTODESK Inventor, a program that let me know what would and what wouldn’t work.

Before I started building the hand I designed it with AUTODESK Inventor, a program that let me know what would and what wouldn’t work.The hand is made out of different materials:

-Iron: for the forearm and palm.

-Steel: for the fingers to offer better resistance

-Aluminum: for the joints of the fingers to provide less friction.

Inside the forearm are six motors, which give movement to the fingers. The type of motors used for the fingers are servomotors with a force of 6Kg and a 10Kg servomotor for the thumb ‘s rotational movement. The motors are connected to a bar that is perpendicular to the axis and this is attached to two nylon strings connecting the tip of the finger to the motor. One thread is for the flexion and the other for extension.

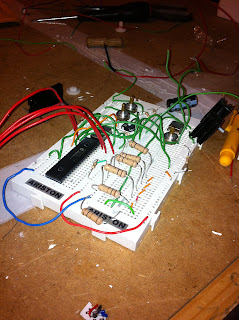

Electric circuit

The circuit is simpler than the programming because of the PICs (Peripheral Interface Controller). The circuit is made up of two PICs:

-PIC18F4520: This PIC gives orders to other parts of the circuit (serves as the brain of the hand). It is in charge of receiving information from the motors and the glove with sensors which it then processes and gives orders.

-PIC18F2420: This PIC controls the position of the fingers. It was possible to use only one PIC but because the communication between the motors was complicated we decided to use two.

-Sensors, buttons and lights are connected directly to the PIC.

-Oscillator of 20MHz is in charge of making the PIC do every action.

Glove with sensors

Flex sensors are sewn to the glove which varies its resistance when bent. These flex sensors with the right amount of resistance causes a voltage divider that allows the PIC to know the position of the fingers facing the voltage between the resistances.

Programming

The hand is programmed in C and is divided into different parts. The program begins with defining all the variables, places of memory…then it starts the interrupt routines, timers and LCD screen. Once this is done, the program looks at the glove sensor values and sends the information to the next PIC to move the fingers. It also makes sure the motors are not overloaded or forced. If they are, it turns the motors off and gives warning that there is a problem. Also, the program has a part dedicated to reading the characters on the LCD screen. Lastly, there is an emergency button on the arm that can turn off the motors.

No comments:

Post a Comment